Infra-red imaging (Thermography) is based upon the science of infrared energy (otherwise known as “heat”), which is emitted from all objects. This energy from an object is also referred to as the “heat signature”, and the quantity of radiation emitted tends to be proportional to the overall heat of the object.

Thermal cameras or thermal imagers are sophisticated devices comprised of a sensitive heat sensor with the capacity to pick up minute differences in temperature. As they gather the infrared radiation from objects in a particular environment, they can start to map out an image based on the differences and inflexions of the temperature measurements.

Thermography is used throughout industry as a key diagnostic tool for detecting problems. Thermal imaging is a non destructive, non contact, cost effective way to detect small problems before they become large problems.

Heat is often an early symptom of equipment damage or malfunction, making it important to monitor in preventive maintenance programs. Using thermal imaging preventive maintenance regularly to check the temperature of critical equipment allows you to track operating conditions over time and quickly identify unusual readings for further thermography inspections.

We specialize in the Thermal imaging applications listed below.

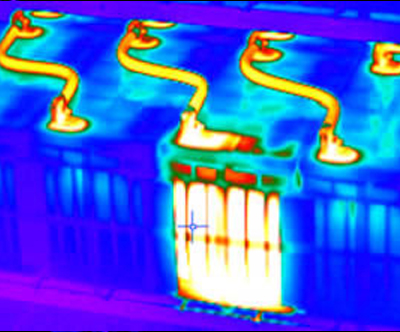

Main incoming power systems

Power subsystems

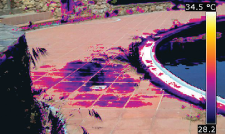

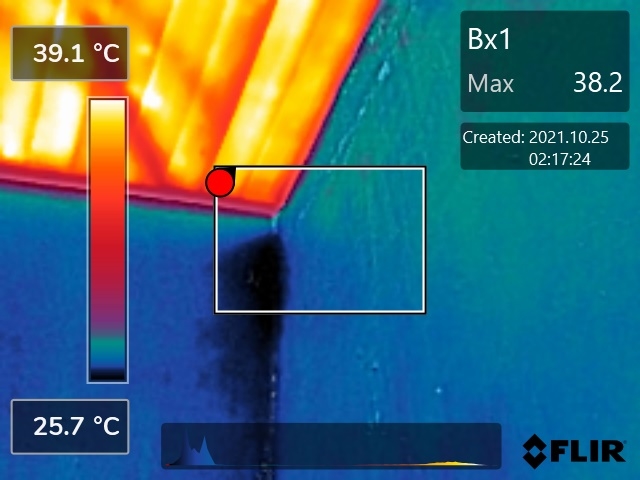

Solar panels and Solar systems

Pool leak detection

Computer/Cryptocurrency servers and server farms

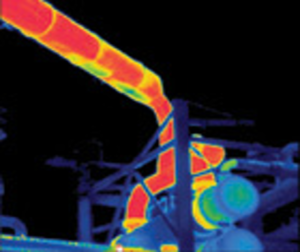

Mechanical systems and components

Building mechanical systems

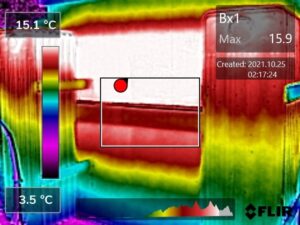

Building water ingress and % moisture detection

Heating and air conditioning loss inspection