Below are some of the industrial benefits an industrial thermographic scan.

Industrial Substation providing incoming power

Increased safety/reduced downtime from electrical fires or failures in the main incoming substation. Failures due to high voltage arcing, transformer overheating, corrosion and hot spots of conductors or ring bus can be reduced or eliminated by a timely thermographic scan. Cost saving include component replacement cost, labor for replacement and business cost of production facility downtime.

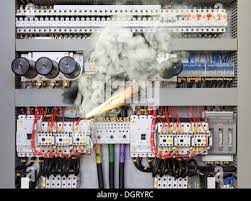

Industrial motor control center providing distribution power

Increased safety/reduced downtime from electrical fires or failures in the distribution/MCC areas. Failures due to loose connections, faulty starters, insulation overheating, cable hot spots can be detected and corrected before an imminent failure occurs. A thermographic scan will “see” these problems before the become a failure. Increased safety for personnel in switch rooms from smoke inhalation. Cost saving include component replacement costs, labor costs and lost production costs.

Automation control panel

Increased process uptime from automation system overheating failures. Failures due to hot automation/network switch failures can be detected and corrected before a major site process interruption occurs in the PLC/DCS system controlling the plant. Cost savings include expensive network switches/components expensive PLC/DCS CPU hardware and associated control cards. There is also a cost savings to localized or plantwide automation interruption.

Cryptocurrency mining computer

Increased reliability and uptime for computer/cryptocurrency servers and server farms. A thorough thermal scan will detect the possible overheating of computers, network switches and power supplies. Cost savings are prevention of computer systems on computer component failure due to overheating. Cost savings of potential customer loss due to unexpected failure.

Motor bearing failure

Increased reliability and uptime of electric motors. A thermal scan of electric motors and drive equipment will detect motor bearing problems caused by over tensioning of belts or front motor bearing heating due to mechanical misalignment. Also motor winding over temperatures due to overloaded/overworked motors. Cost savings are derived from premature motor failure and loss of process/production

Power generation using wind turbine

Increased reliability and uptime of mechanical components including – pumps and pump bearings, gearboxes, conveyor belting and rollers, mill bearings etc. A thermographic scan can detect heat buildup due to lack of lubrication, heat due to components rubbing, bearings in an advanced state of failure. Cost savings will manifest as maintenance done in a timely fashion as opposed to unplanned failures causing facility downtime.

Hot metal vessels

Increased reliability and uptime of hot metal vessels. A thermographic scan can detect voids in refractory which left unchecked could cause hot metal cutouts. Cost savings can be realized by failure prevention of hot metal furnaces, flues, skimming pots etc.

Steam traps and steam piping systems

Increased efficiency of steam and steam piping systems. A thermographic scan can detect steam leaks, steam relieve valves malfunctioning, steam traps not cycling. Cost savings are in the form of more efficient use of steam power.

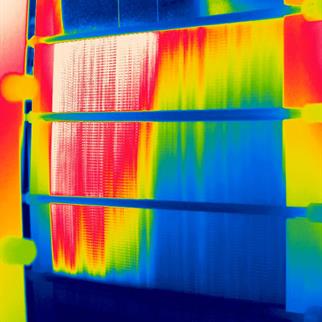

Heat exchanger showing some blockage

Increased efficiency of heat exchangers. A thermographic scan will detect if heat is being evenly distributed across a heat exchanger or if tubes are plugging up. Cost savings are in efficiency gains of the heat exchangers and unplanned downtime.